Danger Lurks In Your Inventory

Inventories are usually made up of many types of stock. There are fast-moving and slow-moving products. There are products with a high profit margin and products with low profit margins. Some products are in demand and other products past their peak. To simply look at an inventory as having a single ‘value’ can be very misleading.

At the bottom end of the inventory process is a warehouse full of dead items past their prime and can’t be sold for anything like their cost of acquisition. It’s truly amazing how much of this ‘dead’ stock is retained on the books at cost price and lingers in the warehouses of so many companies, adding to the value of their inventories but doing nothing for their sales.

An inventory is a dangerous thing. If it’s not properly managed it becomes the equivalent of money that’s depreciating at an increasing rate and can actually drop below zero value. Be aware of the danger and don’t let this situation develop.

How important is inventory as an asset? It’s probably the largest asset of most SMEs, but it’s by no means the most valuable asset in the business. The most important assets are those that turn the inventory into cash – the sales team, the marketing and the business’ customer relationships. That’s what keeps the business ticking over, not just a bloated inventory waiting to be sold.

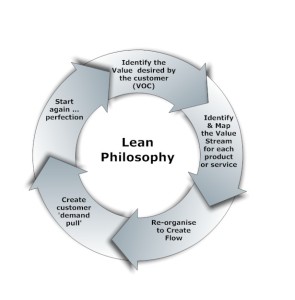

Some businesses manage to trade quite profitably without an inventory of their own. ‘Just in time’ manufacturing processes created a whole new outlook on parts inventories that made maintaining huge stockpiles of components obsolete and saved manufacturers a lot of money. This line of thinking can be successfully applied to just about every inventory situation.

This taught businesses the importance of accurate sales forecasting – knowing what the demand for a product would be and when it would arise. Orders for components could be placed according to the projected demand and the need to retain year round inventories was eliminated.

Most proprietors at least know their sales volumes and would no doubt like to retain them. The catch is how can they do this and at the same time operate with a reduced inventory? If every item in the inventory turned over at the same rate this might be a problem, but a careful analysis of what’s in any inventory will find some fast movers as well as some items that have a much slower path to customers.

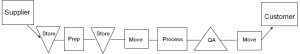

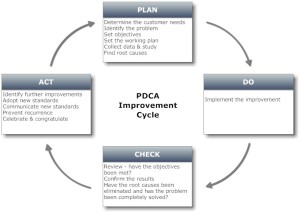

Go through the inventory in detail. Look at the age of what’s in stock as well as how quickly each item turns over and the search will soon find some real opportunities to cut down on the number of items there. It’s also possible to discover some items in the inventory that haven’t moved for so long they’re virtually obsolete. So it’s not just the total value of an inventory that’s important; it’s what it consists of bit-by-bit.

Now look at the profit margins the business earns on each item in the inventory. Relate this to the turnover rate for each item and some surprising facts will emerge. Finding items that turn over slowly and generate low profit margins should ring a huge alarm bell that perhaps these products can be either dropped from the range or sourced from suppliers ‘on demand’.

Inventory on its own doesn’t sell itself. Certainly a business wants to be able to provide its customers with fast-moving, high margin items with the least possible delay, and that’s where the focus should be. In most SMEs the ‘80/20’ law applies to the products they sell – 80% of the turnover comes from 20% of the products. It makes sense to have those 20% of products dominate your inventory and find alternative ways to handle the less-important 80%.

If an organization’s inventory is made up mostly of those ‘80%’ products it’s time to do some housecleaning. All they’re doing is depreciating from year to year and that capital could be better employed in selling more of the 20% products. Even if items in the old inventory will someday be moved, wouldn’t it be better to let someone else have the joy of buying and stocking them? Liquidate them and free up the capital for more productive uses. They can always be repurchased when and if required.

Always remember that an inventory represents cash just sitting there. It’s not cash in the bank; it’s cash that’s been invested and on which needs to generate a return. Everything in an organization’s inventory has a cost attached to it – just acquiring and warehousing it can be expensive, and the longer it’s unsold the higher the costs become.